AFS-1000 Control System by HF Controls

AFS-1000 - Critical Control System

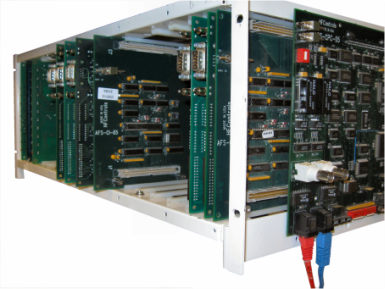

The AFS-1000 Critical Control System accomplishes the wide range of critical equipment control task found in today's power and nuclear plants. Modern, proven and flexible, the AFS-1000 Critical Control System incorporates the latest in technology.

Typically used for applications requiring a high degree of system integrity and dedicated control, the AFS-1000 Critical Control System is versatile and maintenance-oriented. Control cards are arranged with their respective input/output cards, and all cards are accessible and replaceable with the system online. Convenient front-mounted indicators on all cards keep operations and maintenance personnel informed of the system's status.

A distinguishing feature of AFS-1000 is its single-loop integrity. A specific input and output are tied to a single and unique controller, guaranteeing that critical control loops are monitored and controlled without interaction of other loops. Flexible design allows the AFS-1000 Critical Control System to be configured to meet your special requirments. A complete library of general and special purpose input/output cards is available to interface with the complete scope of your plant equiptment and field sensing devices.

The AFS-1000 critical control system consists of five major components: Multifunction Controllers, Input/Output (I/O) modules, Applications Software, Industry Standard Communication Networks, and the Advanced Operator Interface Workstations. These components combine to deliver an exceptional process automation solution that not only optimizes plant performance and efficiency, but also is an extension of management's daily decision making tools.

COMPONENTS

Controllers

Because scalability is necessary for both small and large systems, HFC offers a variety of controllers that can be intermixed throughout the system to optimize system configuration. With advanced, powerful digital and analog central algorithms, the multifunction controllers can be configured online or offline using a programming utility incorporating simple function blocks for control applications.

I/O Modules

The control system I/O modules are comprised of a complete family of digital and analog input and output boards. The I/O modules provide a host of advanced technological features offering a secure and dependable interface to field devices. The intelligent I/O supports a multitude of features such as built-in continuity monitoring, motive power, and status feedback for complete plant control and monitoring functions. Sophisticated diagnostics provide operators with a virtual extension of their senses into the heart of the operation.

Control Room

Three workstation configurations make up the components of the control room. Efficient plant operation is easily achieved through Microsoft® Windows® 10 based workstations: the operator workstation, engineering workstation, and the HIFR PC's. With the Windows® 10 environment, all workstations support interactive color displays, multi-window displays, and a standard library of symbols to allow complete customization. To provide a real-time interactive environment, the control room workstation displays are updated with current values at a rate of once per second. Workstations are connected to the system through industry-standard communication protocols, allowing access to any database point in the system. Each system can be connected to other computers and control systems on the network through the use of a standard Ethernet™ LAN and TCP/IP links.Applications Software

HFC incorporates an innovative approach to software design and integration services that allow information obtained from local and remote I/O, data links to other devices, or output variables from controls strategies to be shared by other software applications and devices. Implementing changes to the system logic as well as customizing logic for a specific application is simple and does not require specific programming knowledge or software training. A built-in programmable feature also allows construction of the control system before operational logic is completed, minimizing the cost of field logic changes. These design tools along with the industry standard hardware and open architecture communications result in a high-speed, reliable, and fully integrated system that is capable of meeting any process control requirements.

Communications Network

The HFC communications network is the most flexible network available today. For interface with our advanced CRT operator and engineering workstations, high-speed, open architecture technology provides a 100Mb/sec TCP/IP local area network (LAN). Communication gateways and hubs enable easy connection to multiple workstations as well as allow access to plant control operation from offsite locations.

FEATURES

- Open architecture permits communication with virtually any external host system or existing distributed control system (DCS)

- Redundant architecture of critical components ensures that no single-point failure can prevent the system from assuming a fail-safe state

- Modular design permits linking multiple controllers within a single system on a common local area network (LAN)

- Input/output (I/O) modules include onboard microprocessors and signal conditioning hardware

- Configurable control operation for fail-in-place and fail-safe control operation