HF Controls Corporation News

News and Announcements From HF Controls

Check this page to learn about new and completed projects, job openings, new hires and more news stories at HF Controls Corporation.

For media inquiries, please contact: daniel.han@hfcontrols.com

May 2021

HF controls has been approved as a qualified supplier of Shandong Polymer, China

HF controls has been approved as a qualified supplier of Shandong Polymer Biochemical Engineering Co., Ltd, and listed in Polymer’s supplier management system, as HFC’s safety control/protection system (DCS/SIS) meets supplier management regulations of Shandong Polymer Biochemical Engineering Co.,Ltd. upon review.

HF controls has been approved as a qualified supplier of Shandong Polymer Biochemical Engineering Co., Ltd, and listed in Polymer’s supplier management system, as HFC’s safety control/protection system (DCS/SIS) meets supplier management regulations of Shandong Polymer Biochemical Engineering Co.,Ltd. upon review.

Shandong Polymer Biochemicals Co., Ltd was founded in 1996 and successfully listed on the Shenzhen Chian Stock Exchange market on September 15, 2010 (stock code: 002476). The company is located in the Yellow River Delta near the Bohai Sea. It is a subsidiary of Changan Group of Shengli Oilfield and a State-level High-Tech enterprise. Polymer has Sharp Energy Co., LTD., Dongying Treasure in Canada's Oil and Gas Exploration and Development Co., LTD., Dongying Polymer Environmental Engineering co., LTD., Xinjiang Environmental Engineering Co., LTD., Polymer International (Hong Kong) Co., LTD., Guangdong Treasure Biological Chemical Co., LTD., Tianjin Bohong Chemical Co., LTD. Business covers oilfield chemicals, oil and gas development, technical services and environmental water treatment.

April 2021

BMS Upgrade for New/Indy Catawba Plant in Catawba, SC

HFC has been commissioned to upgrade the BMS control system for a paper mill in Catawba, South Carolina. These are recovery and combination boilers that fire gas, oil, black liquor and wood chips.

New/Indy Catawba plant has had HFC equipment installed since 1984 and as technology has advanced over the years has gone through several upgrades, improving plant performance as well as operator interface.

The Final Acceptance Testing (FAT) will be completed in Dallas, Texas in November 2021. The current plan for installation of the equipment at the site will be in March 2022.

April 2021

BMS Upgrade for NRG Power Plant in Chalk Point, MD

HFC has been commissioned to upgrade the BMS control system for a power plant in Chalk Point, South Carolina. This is a large gas/oil, tangential fired, twin furnace C.E. power plant.

NRG Chalk Point has had HFC equipment installed since 1986 and as technology has advanced over the years has gone through several upgrades, improving plant performance as well as operator interface.

The Final Acceptance Testing (FAT) was completed in Dallas, Texas in August 2019. The current plan for installation of the equipment at the site will be in September 2021.

March 2021

HFC has acquired its HFC-FPGA Platform Safety Evaluation Report (SER) from the US NRC

On March 2021, HFC has acquired its HFC-FPGA Platform Safety Evaluation Report (SER) from the US NRC. The US NRC staff has performed extensive review and evaluation on the HFC-FPGA platform and determined that the HFC-FPGA platform is acceptable for use in safety-related Instrumentation and Control systems.

This is another important achievement for the company after it had acquired HFC-6000 microprocessor-based platform SER in April 2018. With these achievements, HFC has own both microprocessor-based and FPGA-based platform SERs now, and ready to provide platform I&C applications and services to the industry.

March 2021

HFC Was Awarded PAS Replacement Project in Hanul Unit 5&6

HFC was officially awarded Plant Annunciator System (PAS) Replacement in Hanul Unit 5&6, South Korea on February 25, 2021. Each identical Unit consists of a Division A and B cabinet assemblies, and six single bay MUX cabinets. Three MUX cabinets that are common to both units, and the Radwaste cabinet which is independent of both units. Each unit is configured with the identical redundant architecture having two identical controller & I/O racks in order to operate and maintain any critical control functions.

Hanul Unit 5&6 are South Korean designed two-loop 1000 MWe PWR Generation II nuclear reactors, developed by KHNP and KEPCO. HFC is using its proven FPC-08 controllers to evaluate and control more than 5,000 I/O points. The delivered PAS will include a Sequence of Event (SOE) system which tracks every input as it changes. This replacement will enhance the Hanul Unit 5&6 plant availability, reliability as well as its monitoring and diagnostic capability with HFC’s modern and robust digital control systems.

August 2020

Harduaganj project bolier lighting up on28th August 2020

The cooperation project between HFC and Toshiba for supplying and implementing the boiler protection system of the 660MW Harduaganj Thermal Power Station Extension-II, which is owned by Indian Uttar Pradesh Rajya Vidyut Utpadan Nigam Limited, bolier lighting up on28th August 2020.

The cooperation project between HFC and Toshiba for supplying and implementing the boiler protection system of the 660MW Harduaganj Thermal Power Station Extension-II, which is owned by Indian Uttar Pradesh Rajya Vidyut Utpadan Nigam Limited, bolier lighting up on28th August 2020.

HFC uses its TUV SIL3 certified FPC-08 controller based TMR to implement such a boiler protection system. The FPC-08 controller, along with its comprehensive I/O cards, has been used extensively including all of the Korean Nuclear Power Plants (NPPs) ASTS (Automatic Seismic Trip System), KORI NPP Unit 3&4 PAS (Plant Annunciation System), YGN 3&4 NPP Unit 3&4 Interposing Logic System (ILS), and Chinese QinShan NPP Unit 1 SMS (Seismic Monitoring System).

July 2020

Mr. Jongmin Kim Became HFC CEO

Doosan Nuclear Business Group appointed Mr. Jongmin Kim as HFC new CEO effective July 1, 2020. Mr. Jongmin Kim has contributed significantly to HFC by having taken up roles of Lead Project Engineer, Nuclear Project Engineering Manager, and V.P. of Project Engineering. As new CEO, he will aim at bringing more efficiency to HFC organization to navigate through the new business environment and playing a major role in achieving HFC and Nuclear BG's business goals.

Feburary 2019

HFC 2019 NPIC&HMIT Meeting Participation

HFC has participated in the 2019 NPIC&HMIT meeting that was held in Orlando, FL from February 9-14, 2019. NPIC&HMIT is the de facto forum for nuclear instrumentation and control (I&C) and human factors engineering (HFE) professionals to meet with leaders in industry and academia, discover the state of the technology, exchange information, and discuss future directions. At the meeting, HFC has presented a paper titled "Qualification of Logic Conversion Tools for Safety Applications", which provides approaches for qualifying new tools and pre-developed third-party tools in reference to HFC's One-Step automatic logic translation tool. Doosan Nuclear Business Group and HFC co-presented a paper titled "Design and Implementation of a Modern Rod Control System (RCS)". This modern RCS has replaced the older generation RCS in all South Korean twenty-four (24) Pressurized Water Reactors (PWRs) owned by Korea Hydro & Nuclear Power (KHNP). In its ten (10) years of operating history, the modernized RCS has not experienced a Single Point of Vulnerability (SPV), which further confirms its robust design and successful implementation.

February 2018

HFC Hosts International Workshop

HFC will be hosting the 11th International Workshop on the Applications of Field Programmable Gate Arrays (FPGA) in Dallas, on October 8th through 11th, 2018.

The previous international meetings have attracted significant and increasing interest from nuclear utilities, nuclear safety authorities, technical and scientific support organizations, universities, research and development organizations, and technology suppliers. This series of annual meetings is considered now the most representative international meeting on the given subject.

The FPGA workshops contribute to the development of competencies in a specific technical field that remains relatively new to the nuclear industry. In this connection, the annual meetings serve as the basis of a Community of Practice aimed at capturing and transferring knowledge for the wider nuclear community. The continued development of knowledge in this area is essential to the ongoing modernization and new build projects of nuclear instrumentation, control, and safety systems that employ FPGA technology world-wide.

January 2018

HFC Secures Contract with Toshiba

HFC has secured a contract with Toshiba for supplying and implementing the boiler protection system of the 660MW Harduaganj Thermal Power Station Extension-II, which is owned by Indian Uttar Pradesh Rajya Vidyut Utpadan Nigam Limited.

HFC uses its TUV SIL3 certified FPC-08 controller based TMR to implement such a boiler protection system. The FPC-08 controller, along with its comprehensive I/O cards, has been used extensively including all of the Korean Nuclear Power Plants (NPPs) ASTS (Automatic Seismic Trip System), KORI NPP Unit 3&4 PAS (Plant Annunciation System), YGN 3&4 NPP Unit 3&4 Interposing Logic System (ILS), and Chinese QinShan NPP Unit 1 SMS (Seismic Monitoring System).

June 2016

Plant Annunciator System (PAS) Replacement in Kori, South Korea

HFC in in the process of finishing the Plant Annunciator System (PAS) for Units 3&4 at Kori, South Korea. These are each 1,000 megawatt nuclear power units. HFC is using 38 of its FPC-08 controllers to evaluate and control more than 5,000 points.

At the same time HFC upgraded an old PAS system, HFC included a Sequence of Event (SOE) system which tracks every input as it changes. The SOE system can detect a change down to 125 microseconds. After figuring in potential de-bounce of input contacts, the system looks at a 1mS resolution. As per customer input, to eliminate possible false inputs due to noise on field wires, the system will reject any input signal less than 4.5mS in duration.

November 2014

HFC Participates in Petrochemical Automation Association Meeting

HF Controls participated the 13th Chinese Annual Petro-Chemical Automation Association Meeting in Wuxi, China with a booth from Nov 12 thru 15 to promote HFC SIS products. At the same time, HF Controls is looking for potential strategic OEM partners for it. There were many inquiries from local companies about possibilities of join effort to promote our SIS products for Petro-Chemical industry.

November 2014

HFC Welcomes Shanghai Regeon

Welcome Shanghai Regeon Electric Company (Regeon) as one of our strategic partner for promoting HF Controls’ nuclear safety I&C products in China. Regeon has a lot of experiences in supplying I&C equipment to both nuclear and non-nuclear applications. The company has a strong engineering team and experienced manufacturing department.

HOW FAR BACK SHOULD I GO? BELOW ARE STORIES FROM > 5 YEARS AGO:

| Oct 2013 | Awarded New Upgrade Project |

|

HF Controls received purchase orders from Alcoa to upgrade the control system at their Warrick site. Unit 4 was partially upgraded years ago and will now have their DOS-based Engineering Work Station upgraded to a Windows 7-bassed system, will have the inter-controller communication equipment upgraded and will have the directly connected MODBUS link to a separate Honeywell system upgraded to a faster MODBUS-over-TCP/IP communication link while adding a new Windows 7-based Operator Work Station installed for direct input. |

||

| Sep 2013 | HFC Delivered the First Safety Instrument System to China/Taiwan |

|

HF Controls delivered the first HFC-6000 Safety Instrument System (SIS) to Formosa Plastic Company in (FPC) Taiwan. After the Final Acceptance Test (FAT) in Taiwan, the SIS will be installed in FPC’s petrochemical plants in China later this year. This is the result from the two years cooperation of developing a certified safety control platform with Institute of Nuclear Energy Research (INER) in Taiwan. |

||

| Aug 2013 | HFC-6000 Receives SIL 3 Certificate for Second Time |

|

HF Controls receives the second TUV SIL 3 certificate for HFC-6000 safety control system. This time, the certificate is awarded to the Triple Module Redundant (TMR) HFC-6000 with our new HFC-FPC08 controller. Up to today, HFC-6000 has two SIL 3 certificate for both HFC-SBC06 multiple loop controller and HFC-FPC08 high performance controller. Both safety controllers have many installations for safety control processes in nuclear power plants in the past. |

||

| Jun 2013 | Maintenance Contract Completed |

|

HF Controls completed the service and maintenance contract successfully on Plant Control System (PCS) in Ulchin Nuclear Power Plant (UCN) during the outage of Unit 5. As the original vendor of PCS at site, HF Controls is able to diagnose the current system issues and to provide the solution to it. This service and maintenance contract was handled by HF Controls Branch Office in Korea and the technical support from our US based engineers. |

||

| Jun 2012 | HF Controls participates in NIC 2012 Beijing China |

|

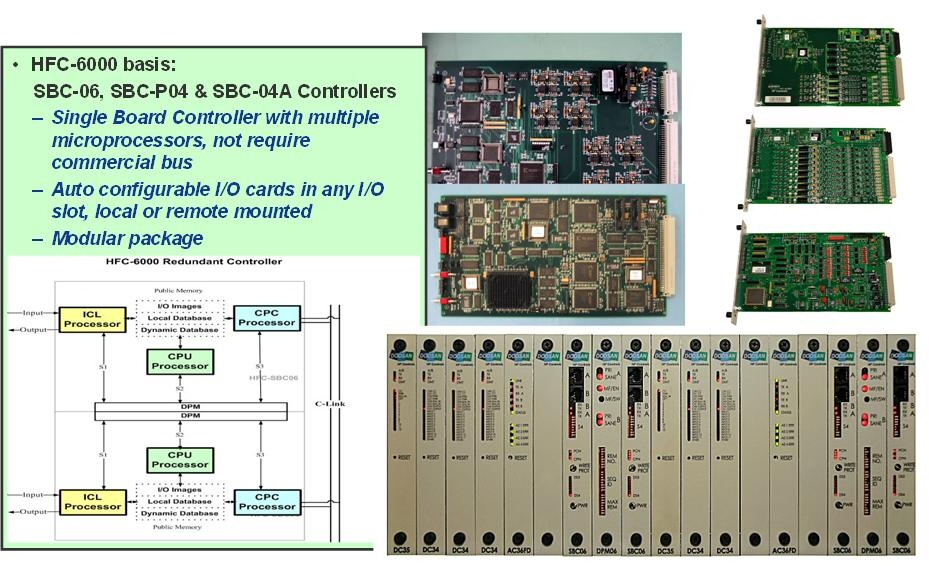

HF Controls, a nuclear Digital Instrumentation and Controls (I&C) vendor located in Texas, USA, participated in the NIC 2012 Exhibition for the first time. Digital I&C systems - based on computers and microprocessors, are the nervous systems of a nuclear power plant that monitor all aspects of the plant’s health and help respond with the care and adjustments needed. Digital I&C systems offer highest reliability, better plant performance and additional diagnostic capabilities. Analog systems will gradually become obsolete. About 40% of the worlds operating reactors (~450) have been modernized to include at least some digital I&C systems. The current nuclear power plants that are in construction and are planned to be constructed will be digitized in most of their I&C systems. Safety-related digital I&C systems, for example, Reactor Protection Systems and Engineered Safety Features Actuation Systems, are key technologies in the nuclear I&C systems. The safety-related I&C systems must be thoroughly reviewed and be qualified and approved by the government nuclear safety regulators before they are used in the nuclear power plants. For the past twenty years, HFC has developed and manufactured a family of controller systems to control pumps, valves, circuit breakers, motor starters, and solenoid valves as well as monitor the status of the process under control. These control systems have been used for a wide variety of commercial processes, including nuclear power plants in the safety-related as well as non-safety-related applications. HFC is an active I&C equipment vendor in South Korea and have installed control equipment to all four Korean nuclear sites including Yonggwang, Kori, Wolsong and Ulchin. In the past 15 years, the South Koreans have installed 12 units, 1000 MW Korean Standard Nuclear Power (KSNP) plants. HFC provided the Plant Control System (PCS) to eight (8) units of these twelve (12) units. The PCS controls up to 80% of the equipment in the plants and includes both nuclear class 1E and non-class 1E control systems. HFC also provided several retrofit control systems to help the existing plants to upgrade aged I&C equipment such as Alternative Diesel Generator control systems (AAC D/G), and Safety Video Display Unit (SVDU) (similar SVDU have been supplied to the Spanish ASCO Units 1&2 Nuclear Power Plant). In addition, HFC worked with Doosan Heavy Industries to design and test a Nuclear Steam Supply System (NSSS). Currently, South Korea is moving into 1400MW next generation nuclear power plants. As part of the localization policy, HFC has adjusted its role to perform design and development work for the I&C division of Doosan nuclear business group. HFC has been participating in I&C equipment development work for Shin Ulchin (SUN) 1&2 aggressively. The scope of the work includes both I&C development engineering and nuclear application engineering. Just for this year alone, HFC received more than half dozen engineering projects from its parent company. HFC is instrumental in helping South Korea to realize its nuclear I&C technology localization. The original design of HFCs digital control system for Duke Powers nuclear application became the first digital I&C installation in the South Korean nuclear power plant (YGN 3&4) in the early 1990s. Installation of thousands of microprocessor- based single loop controllers marked the first step away from analog control circuitries to digitize the entire plant protection, control, and status monitoring. Since then, for a period longer than 10 years, the South Korea Power Engineering Company (KOPEC) has localized its I&C engineering process. HFCs modernized HFC-6000 & ECS-1200 nuclear control system became the first installation of multiple loop controllers in South Korean nuclear power plants. Meanwhile, several Distributed Control Systems (DCS) had been started to apply to the non-critical control area such as the Radwaste control system. The I&C equipment evolution process provided chances to gain mature experience for KOPECs nuclear I&C engineering and accumulative maintenance skills for Korean utility customer, Hydro & Nuclear Power Company (KHNP). Since the nuclear industry localization is the long term policy and commitment for the South Korean government, HFC has been an important contributor to the South Korean nuclear industry to reach its goal of possessing the current most advanced nuclear plants I&C. Last April, HFC obtained the US NRC SER for its safety-related platform HFC-6000 (see Figure 1). This is an important milestone in the qualification of a safety system and is a useful basis for any company using the platform. Such qualification simplifies the local licensing process and is ready for immediate applications. HFC is only the fourth vendor to obtain such qualification. Mr. Robert Contratto, Vice President Marketing and Sales of HFC and Dr. Steve Yang, Chief Consultant of HFC represented HFC at the NIC 2012 meeting in Beijing (see Figure 2). Dr. Yang is an international expert on the digital I&C and safety-related software verification and validation. He visited China a few times including an invitation presentation on the US digital I&C experience for China State Nuclear Power Technology Company and an invitation presentation on DCS V&V for the Nuclear and Radiation Safety Center (NRSC). Dr. Yang strongly believes that HFC can provide an immediate solution with long term benefits to the China qualified 1E nuclear I&C platform need and fill the void for the Chinese Nuclear Industry. This is because HFCs platform is not only reviewed most extensively and qualified but also proven and reliable. According to Dr. Yang, the digital I&C is a very specialized and knowledge intensive field. The size of the company does not matter. However, the know-how and flexibility matter. HFC has the nuclear I&C knowledge and the HFC system is flexible and scalable, suitable for any size of the nuclear I&C projects. HFC is willing to cooperate with China through technical transfer with a comprehensive training program. This will be a successful cooperation between HFC and China and will benefit the Chinese Nuclear Industry in particular and the greater industries in general. Figure 1 HFC-6000 high integrity product basis

Figure 2 - Mr. Robert Contratto (the first from the left) and Dr. Steve Yang (the third from the left) with engineers from China Nuclear Control System Engineering Company.

|

||